Report: PERMAKOTE® — The High-Performance, ENERGY STAR® Certified Roof Coating System

PERMAKOTE is a state-of-the-art acrylic elastomeric roof coating designed to deliver exceptional waterproofing, thermal insulation, and protective performance. Engineered with advanced ceramic and borosilicate technology, this coating meets or exceeds ENERGY STAR® guidelines for energy efficiency. Its innovative formulation ensures superior energy savings, longevity, and environmental sustainability, making it an industry leader in protective coatings.

Key Features and Benefits of PERMAKOTE

ENERGY STAR® Certification

PERMAKOTE is ENERGY STAR-certified, ensuring it meets rigorous energy efficiency criteria. By reflecting up to 95% of solar heat, it reduces roof temperatures, lowers cooling costs, and minimizes environmental impact.

Thermal Insulation

- Ceramic Technology: Incorporating NASA-inspired ceramic insulation, PERMAKOTE offers thermal performance comparable to traditional insulation materials. When applied at 25 mils dry film thickness, it achieves an R-value of up to R-17.

- Thermal Testing Results: Testing shows that PERMAKOTE reduces indoor temperatures by as much as 12.2°C compared to uncoated surfaces, providing significant cooling benefits in hot climates like the UAE and GCC Region.

Waterproofing Excellence

Designed to prevent water infiltration, PERMAKOTE protects against leaks, structural damage, and hydrostatic pressure. It forms a seamless, durable bond, resisting high wind-driven rain speeds and extreme weather conditions.

Durability and Safety

- Fire Resistance: PERMAKOTE has a Class A Fire Rating under NFPA 101 standards, providing enhanced safety for buildings.

- Long-Lasting Protection: Backed by a long warranty, it offers resistance against peeling, chipping, and cracking.

Eco-Friendly and Sustainable

PERMAKOTE is manufactured with low and zero-VOC formulations, ensuring it is safe for indoor use and environmentally friendly. Its energy-saving features align with global sustainability goals.

Applications

PERMAKOTE is highly versatile and suitable for:

- Residential and commercial roofs (flat and sloped).

- Industrial facilities requiring thermal and waterproofing protection.

- Energy-efficient upgrades for existing structures.

- Areas prone to extreme weather conditions, such as the UAE and GCC.

Testing Section: Validating PERMAKOTE’s Thermal Performance

Comprehensive testing was conducted to assess the thermal insulation and waterproofing capabilities of PERMAKOTE. These tests, performed in controlled environments, compared its performance to uncoated surfaces and 100mm polystyrene insulation.

Testing Procedure

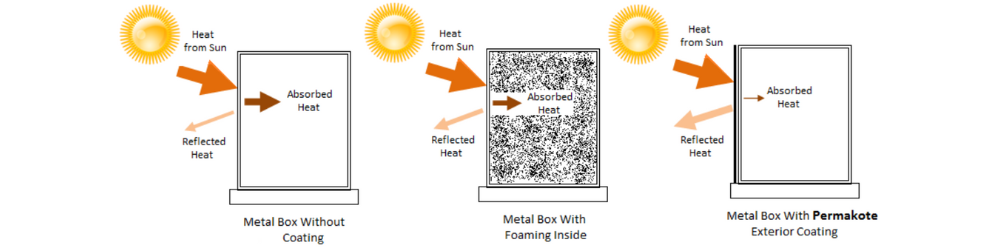

The testing procedure involved three distinct setups to evaluate thermal performance: a metal box without coating, which served as the control to establish baseline performance; a metal box insulated with 100mm polystyrene boards, representing traditional insulation methods; and a metal box coated with PERMAKOTE, showcasing the advanced capabilities of the coating. All setups were exposed to direct sunlight for one week to simulate the harsh environmental conditions typical of Dubai and the GCC region. Sensors were installed inside and outside each setup to record external, internal, and ambient temperatures at regular intervals, ensuring accurate and comparable data collection across all configurations.

The diagram above illustrates the heat dynamics in the three setups. It highlights how PERMAKOTE effectively reflects heat, minimizing absorption and maintaining cooler internal temperatures compared to the other configurations.

Results

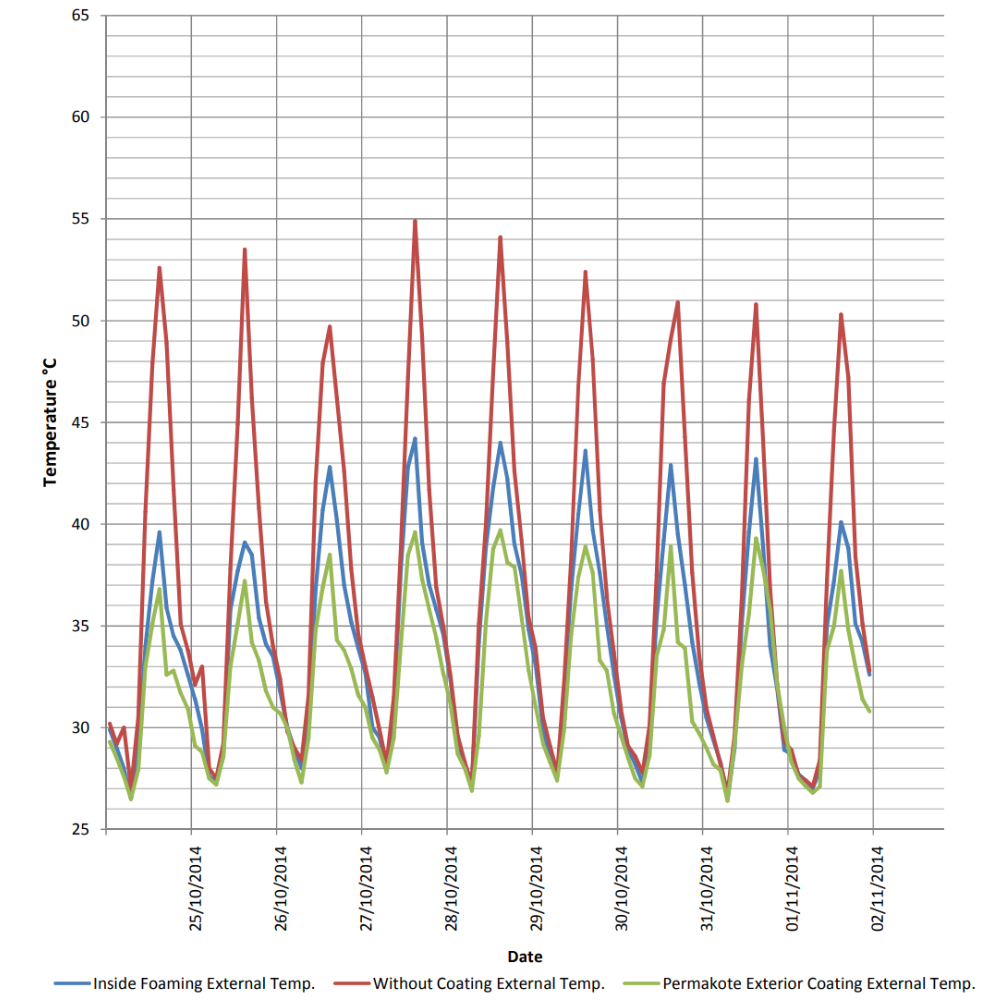

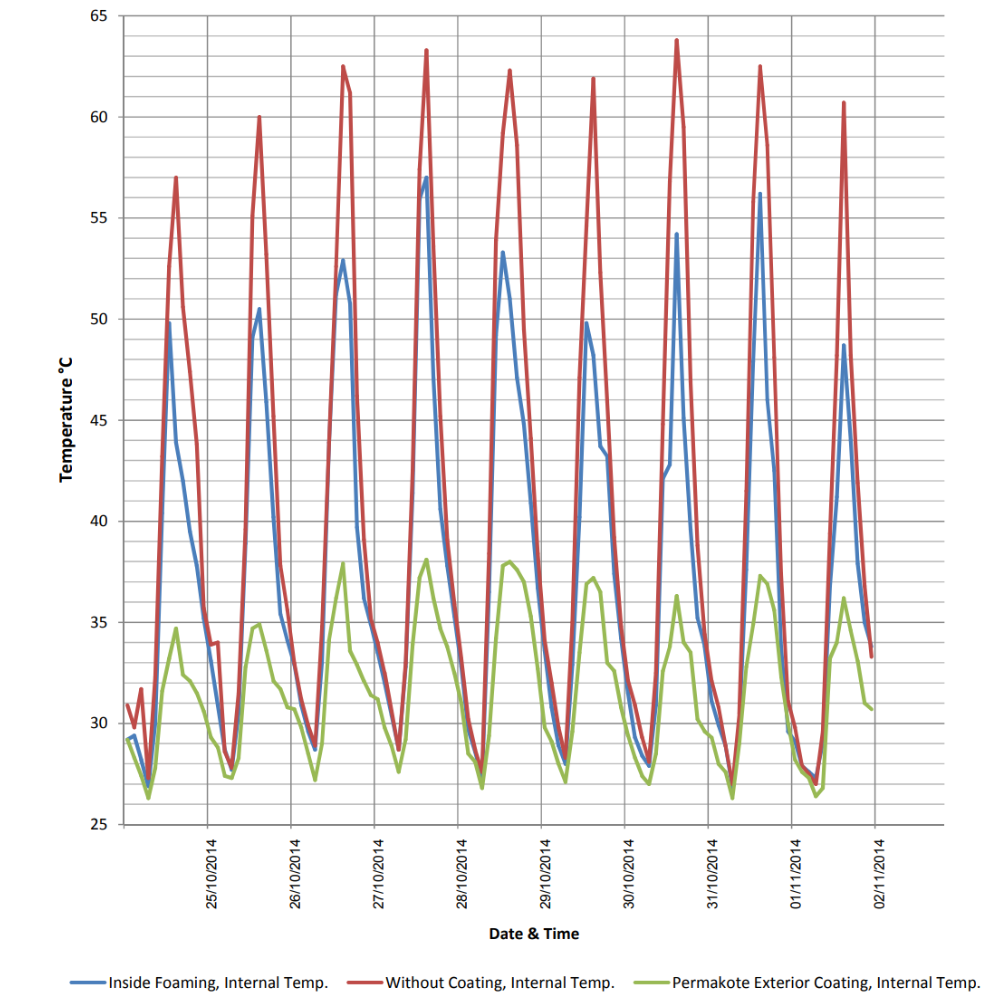

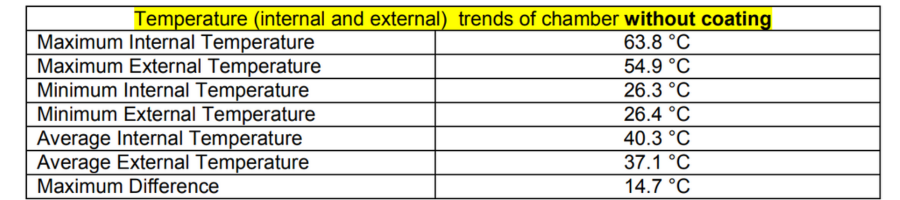

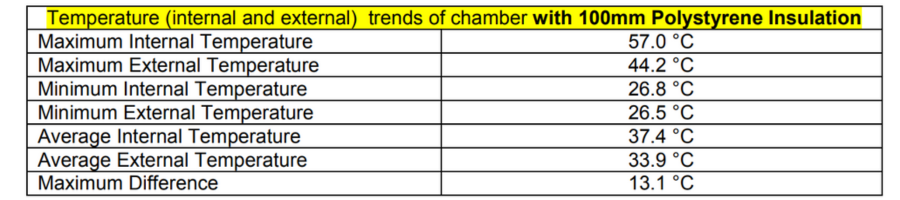

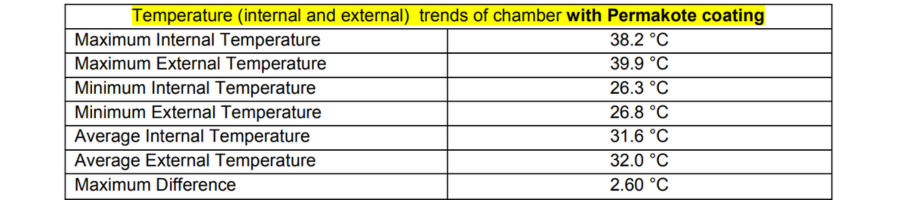

Below are graphical representations of the external (left) and internal (right) temperatures recorded for all chambers.

Key Findings

Temperature Control: Chambers coated with PERMAKOTE maintained an average internal temperature of 31.6°C, significantly cooler than uncoated chambers (40.3°C) and chambers insulated with 100mm polystyrene (37.4°C).

Temperature Variation: PERMAKOTE showed minimal internal temperature fluctuations, with a maximum difference of 2.6°C, compared to 14.7°C in uncoated chambers.

Download the Full Testing Report

For detailed results, including comprehensive tables and graphical analyses, request the full PERMAKOTE testing report.

Why Choose EnergyZone LLC & PERMAKOTE?

Energy Efficiency and Sustainability

Our products meet and exceed ENERGY STAR® guidelines, offering superior energy efficiency, durability, and environmental compliance.

Proven Expertise

With over 20 years of experience, EnergyZone LLC has become a trusted provider of advanced coatings in Dubai and across the GCC region.

Exceptional Support

From application guidance to post-installation support, our team ensures every project achieves optimal results.

Explore more about PERMAKOTE on our product page or request a consultation for your project.